SHE BUILT IT

Challenging the Plasticine Peabrains that Blithely surrender to Regimantation I say ................................................ SHE BUILT IT!!!

Monday, December 31, 2007

Sunday, December 30, 2007

Friday, December 28, 2007

Tuesday, December 25, 2007

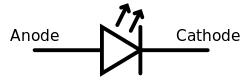

Advantages of using LEDs

- LEDs produce more light per watt than do incandescent bulbs; this is useful in battery powered or energy-saving devices. [19]

- LEDs can emit light of an intended color without the use of color filters that traditional lighting methods require. This is more efficient and can lower initial costs.

- The solid package of an LED can be designed to focus its light. Incandescent and fluorescent sources often require an external reflector to collect light and direct it in a usable manner.

- When used in applications where dimming is required, LEDs do not change their color tint as the current passing through them is lowered, unlike incandescent lamps, which turn yellow.

- LEDs are ideal for use in applications that are subject to frequent on-off cycling, unlike fluorescent lamps that burn out more quickly when cycled frequently, or HID lamps that require a long time before restarting.

- LEDs, being solid state components, are difficult to damage with external shock. Fluorescent and incandescent bulbs are easily broken if dropped on the ground.

- LEDs can have a relatively long useful life. One report estimates 35,000 to 50,000 hours of useful life, though time to complete failure may be longer.[20] Fluorescent tubes typically are rated at about 30,000 hours, and incandescent light bulbs at 1,000–2,000 hours.[citation needed]

- LEDs mostly fail by dimming over time, rather than the abrupt burn-out of incandescent bulbs.[21]

- LEDs light up very quickly. A typical red indicator LED will achieve full brightness in microseconds; LEDs used in communications devices can have even faster response times.

- LEDs can be very small and are easily populated onto printed circuit boards.

- LEDs do not contain mercury, while compact fluorescent lamps do.

LED evolution could spell the end for light bulbs

| Bradley Chambers checks out a display at the Lightfair International lighting convention. | ||

| Gregory Bull, AP | |||

But on seeing a light bulb, he might say, "Ah! Here's something I recognize. A few of those grace my home, too."

If the visitor comes back in 15 years, the fruit of Thomas Edison's bright idea may be gone. The likely replacement: light-emitting diodes, or LEDs.

LED lamps were unthinkable until the technology cleared a major hurdle just a dozen years ago. Since then, LEDs have evolved quickly and are being adapted for many uses, including pool illumination and reading lights, as evidenced at the Lightfair trade show here this week.

More widespread use could lead to big energy savings and a minor revolution in the way we think about lighting.

LEDs have been around since the 60s, but have mostly been relegated to showing the time in an alarm clock or the battery level of a video camera.

They haven't been used as sources of illumination because they, for a long time, could not produce white light — only red, green and yellow. Nichia Chemical of Japan changed that in 1993 when it started producing blue LEDs, which combined with red and green produce white light, opening up a whole new field for the technology.

And the industry has been quick to exploit it. LEDs are based on semiconductor technology, just like computer processors, and are increasing in brightness, energy efficiency and longevity in a way that's reminiscent of the way each year's new crop of processors is faster and cheaper than last year's.

Just this week, researchers at the Lighting Research Center at Rensselaer Polytechnic Institute in Troy, N.Y., said they had boosted the light output per watt of a white LED to almost six times that of an incandescent light bulb, beating even a compact fluorescent bulb in efficiency.

The current generation of mass-produced white LEDs is not as effective. It's about twice as good as a light bulb of the same wattage, but the energy savings aren't enough to overcome the major drawback of being expensive.

"It's hard to convince consumers based on energy savings alone," said Nadarajah Narendran, director of lighting research at Rensselaer. "If you look at compact fluorescent lamps, they're four times as efficient as incandescent lights, and how many homes have those? It's less than 5% penetration."

But development is brisk, and the Department of Energy has estimated that LED lighting could cut national energy consumption for lighting by 29% by 2025. The total savings on U.S. household electric bills until then would be $125 billion.

LEDs have other advantages that are propelling them into niche uses, despite their upfront cost.

Current white LEDs will last up to 50,000 hours, about 50 times as long as a 60-watt bulb. That's almost six years if they're on constantly.

That makes them attractive for places where changing bulbs is difficult or expensive — like on the outside of buildings or in swimming pools. Osram Sylvania, the lighting subsidiary of German manufacturer Siemens AG, makes 27-foot long strips of flexible, adhesive tape covered in LEDs for such applications.

Hotels are interested in using LEDs in bedside lamps to save them the trouble of replacing burned-out bulbs, said Jim Anderson of Lamina Ceramics, which showed off a 6-watt array of LEDs that produce light equivalent to a 20-watt halogen bulb.

LEDs are also durable. Being solid-state, they can resist the vibrations in aircraft and cars, according to Narendran, who has worked with Boeing Co. on designs for aircraft cabins.

General Electric Co. and smaller iLight Technologies of Evanston, Ill., make glowing LED signs that look like neon.

Neon lighting is a leading cause of fires at restaurants and the signs are vulnerable to vandalism. By contrast, LED signs made of Plexiglas are tough. At the trade show, iLight exhibited an LED sign that still worked after taking a blast from a shotgun.

The limitation: iLight's signs can't be made economically on a one-off basis, as done at small neon-sign shops around the country.

The feature of LEDs likely to propel them into homes is aesthetic, not practical. Arrays that mix red, green and blue LEDs can produce any color of the rainbow. Instead of a dimmer, you might have three sliding knobs that let you mix color.

"On a very hot day you might want blue light to cool it down a bit, or on a winter day you may want to simulate sunlight," said Steve Landau of Lumileds Lighting, an LED-making joint venture of Agilent Technologies Inc. and Philips Lighting.

Qantas Airways Ltd., the Australian airline, recently outfitted its first-class cabin with LED lighting that shines a deep blue when it's time to sleep.

A system like that would be too expensive for most homes, but industry experts believe the price will come down in a few years as the technology develops.

"We are still in a very young research environment," said Norbert Hiller, vice president at Cree Inc. of Durham, N.C., which produces blue and green LEDs. "Our researchers keep surprising us."

Copyright 2005 The Associated Press. All rights reserved. This material may not be published, broadcast, rewritten or redistributed.

|

Friday, December 21, 2007

Thursday, December 20, 2007

Today ready to be filled with DRI-Core

Today ready to be filled with DRI-Core Yellow incandescent vs white led

Yellow incandescent vs white led Notice the white spot as opposes to no spot on left. Same light different configuration

Notice the white spot as opposes to no spot on left. Same light different configuration 6 months, 5 sample orders to find the perfect stone let's hope the final order ( all pieces) look as good

6 months, 5 sample orders to find the perfect stone let's hope the final order ( all pieces) look as good

Highly polished Copper Slate. will be a combination of copper and Grey tones. Side piece is for comparison only

Tuesday, December 18, 2007

Natural Florida Cypress

Click Image to enlarge

1. Used in The Guest Ceiling and The Stage Ceiling.

2. All Window and Door casings and the exterior Tongue and Groove Shutters were also made from Natural Florida Heartwood Cypress

North American Cypress (Taxodium distichum), grows in wet, swampy areas along the Eastern Coast from Delaware to Florida and west along the Gulf to the Mexican border in Texas and north up the Mississippi River Valley. This water-loving tree grows best in the swampy areas of Florida and the lower Mississippi river and can reach heights of up to 145 feet. Common names for cypress include: Baldcypress, bald cypress, cypress, swamp cypress, southern cypress, red cypress, yellow cypress, white cypress, tidewater cypress, gulf cypress, black cypress, cow cypress

Cypress trees are one of two American conifers (softwoods) that shed foliage in the fall like hardwoods. Although a softwood, it has traditionally been grouped and manufactured with hardwoods because it grows alongside hardwoods and is even graded by the rules of the National Hardwood Lumber Association.

Cypress has many exterior and interior uses. Cypress heartwood is extremely decay and insect resistant due to the naturally occurring preservative known as cypressine. It is an ideal choice for house construction, docks, beams, decks, flooring, paneling and siding. Cypress can also be milled to make doors, windows, rails, and even caskets. The ancient Egyptians used cypress to produce the pharaoh’s caskets, and in the Middle Ages, craftsmen used it to carve enormous cathedral doors.

One Cypress grade that is particularly popular for interior paneling is Pecky cypress. Although the exact cause is unknown, Pecky occurs when the wood is attacked by fungus, resulting in lens-shaped pockets throughout the wood. When finally cut for paneling, it yields an attractive three dimensional look unlike any other wood. Studies have not revealed the exact origin of the fungus or why it attacks only certain trees. Even though Pecky Cypress is considered an independent grade, it is not as readily available as the Selects and Commons and therefore offers a special opportunity to present a truly unique rustic appearance.

Ceiling

Ceiling Window Casing

Window Casing

Shellstone

Click Image to enlarge

- Used in the Guest Bathroom

- Also known as CONCHUELA. It is a unique type of shell stone from the coast of the Gulf of Mexico. The color of this stone ranges from a bright white, like the sea sand, to a soft beige that is produced by shell dust.

- The common pattern is seashells and little croissant incrustations in different sizes with some darker markings. Its natural texture is used for endless applications in interior or exterior, such as tiles for wall covering and fireplaces.

- Great for Pool decks - Does not absorb heat!