|

| | |||||

| |||||||

| Wood Basics | |||||||

| In the USA, there are over 1,000 species of trees. Of these, only about 100 are used for constructing and manufacturing wood products. From this group, it's best to pick the ones that are easiest to work with and most appealing to you. There are basically two kinds of wood from which to choose— hardwoods and softwoods. In addition, there are certain characteristics that are common in all wood types. Here are some common terms and definitions you should know:

| |||||||

| A Closer Look at Wood Grain | |||||||||||||||||

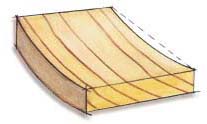

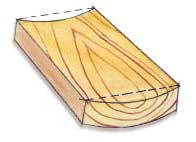

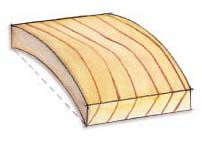

Grain pattern density determines strength. As you'd expect, a piece of lumber with a tight pattern is stronger than one with a loose grain pattern. And when building, a board's strength is maximized when other pieces run across the grain pattern — not parallel to it. | |||||||||||||||||

| Making the Grade |

| When you are choosing lumber, do you know what the stamp on the wood actually means? Fear not! We've deciphered those hieroglyphics for you. So the next time you go to the lumber yard, you'll sound like a pro. |

| Grades of Hardwoods | ||||||||||||||||||||

| Grading designation depends on the number of defects in a given length and width of hardwood boards. As with softwoods, a lower grade can be perfectly acceptable, depending on placement and usage. Hardwoods are graded by the National Hardwood Lumber Association. Here's a chart to help explain the grading system. Grades are listed from highest to lowest.

There are grades below #2 Common, but they are typically not suitable for woodworking. | ||||||||||||||||||||

| Grades of Softwoods | ||||||||||||||||||

| Softwoods are divided into two categories: dimensional lumber, with a grade based on strength, and appearance boards, which are typically used for woodworking projects. Grading of softwoods is overseen by a number of different agencies, so you will be more likely to find some variations in terminology. Grades listed here are from highest to lowest.

| ||||||||||||||||||

| Common Lumber Defects | |||||||||||||||

| |||||||||||||||

| Lumber Grading Stamp | |

While lumber of the same species and size is still at the mill, it is designated and separated by grade. It is then identified by a stamp and often inventoried by its grade and species. When selecting wood, be sure you look for its grading stamp because different lumberyards sometimes use different names for the same grade. (And remember, if you are having trouble figuring it all out, ask for help.) Grade designations depend on particular defects such as knots or wane. Keep your project final results in mind when selecting the grade of wood. Grade does not indicate consistency of color or grain patterns. Manufacturer: Mill's number, name, or symbol. (ex. 12) Certification mark: Symbol of agency providing quality-control supervision. (ex. WWP®) Grade: Often abbreviated. 1 Common shown. (ex. 1COM) Moisture content (MC:) Abbreviation for MC when board surfaced. MC 15 is 15 percent or less; Species mark: Symbol or abbreviation for types of tree. Example shown is Ponderosa pine. (Ex. PP) | |

0 Comments:

Post a Comment

<< Home